REVISED PRE-TRIP INSPECTION

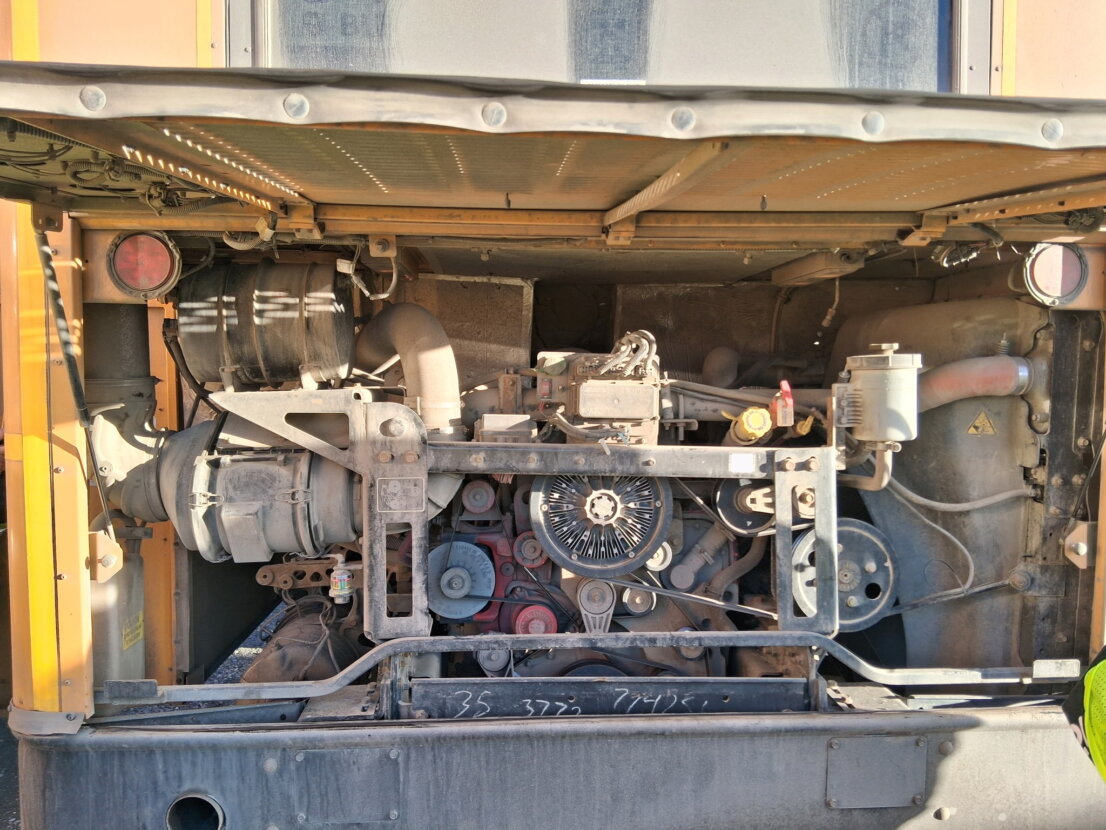

REAR ENGINE

MENTAL PRE-TRIP

- Am I ready?

APPROACH

- Visible Damage to the bus (glass, body damage)

- Bus Leaning (indicating broken leaf spring, shock, flat tire)

- Pools of fluid on the ground

- C-h-o-c-k W-h-e-e-l T-i-r-e-s

UNDER THE HOOD INSPECTION

- Drive shaft & Safety Loop (PMS)

- Cowling (properly mounted and secure, not broken, cracked, or loose, no missing nuts or bolts, latches, function, cowling remains up while open)

- Electrical wires and Light wiring (PMS, properly mounted and secured, wires have no cuts, cracks, or frays, properly put away)

- Air filter gauge (PMS, in the green)

- Alternator (PMS, belt driven, 1/2 to 3/4" slack, wires have no cuts, cracks, or frays)

- Water pump (NO LEAKS, PMS, belt driven, 1/2 to 3/4" slack)

- SERPENTINE BELTS (All belts are adjusted properly with no more than 1/2 to 3/4" slack, Not cut, ripped, or torn.

- Oil (cap is on tight, proper level, no bubbles or discoloration. The way we check the oil is: Engine cool, we take the dipstick out, clean it, put it back, take it out again and check to see that the fluid level is between the fill and full markings.)

- Power steering pump, air compressor (they are gear driven, NO DAMAGE OR LEAKS, properly mounted and secured, not broken, cracked or loose, no missing nuts or bolts)

- Power steering fluid (cap is on tight, proper level as indicated on the outside of container) Checked with transmission is in neutral, engine warm, we take the dipstick out, clean it, put it back, take it out again and check to see that the fluid level is between the fill and full markings.)

- Wires (PMS, not bare or frayed)

- Hoses (no Abrasions, Bulges, Cuts, Cracks, (ABC's) or Leaks)

- Fan and Radiator (secure, not cracked, no leaks)

- Coolant (PMS, NO LEAKS, sight glass shows adequate level)

- Exhaust (PMS, no loose clamps, NO WDC (Welds, Dents, Cracks), rust or carbon soot.)

- Shut the cowling (secure)

RIGHT SIDE OF BUS

BEHIND THE RIGHT REAR TIRE

- Battery Compartment (pms, NO LEAKS, three, no corrosion, switch on)

- Fuel Cap (is tight and secured, NO LEAKS)

- Fuel Tank (PMS, NO LEAKS)

- Oil Pan (PMS, not missing nuts or bolts, NO LEAKS)

- Transmission Fluid pan (PMS, not missing nuts or bolts, NO LEAKS)

SERVICE DOOR AREA

- Service Door (opens & closes easily, glass clean, not cracked or broken, door hinge secure, seals intact)

- Steps (clear, tread is not loose or worn, free of obstructions)

- Handrails (secure)

- Fire Extinguisher (secure, zip tag in pin, gauge in the green, current inspection tag, hose is free of ABC's and debris)

- Triangles (3, sand-weighted and secure)

- Garbage can (secure)

INSIDE THE BUS

SECURE THE BUS

- Park Brake Applied

- Transmission in Neutral

- Shut the door

ENGINE START PROCEDURE

- Turn Key to the right "on" position (without starting)

- Voltmeter (12 to 13 volts)

- Wait 20 to 30 (for the start light to go out)

- Start Engine

- H-i-g-h I-d-l-e "on"

- ABS light (turns off promptly)

- Voltmeter (13 to 14 volts)

- Oil Gauge (needle up in 3 seconds)

- Temperature Gauge (check later "in operating range")

- Air Pressure Gauge (120 to 125 psi)

- DEF Gauge (sufficient fluid, not less than 1/8th)

- Diesel Fuel Level (no less than 1/2 tank)

AIR BRAKE TEST PROCEDURE (6 items)

(Static Air Pressure, Applied Air Pressure, Pump Down, Building Air Pressure, Parking Brake Check, Hard/Soft Brake Check)

STATIC AIR PRESSURE TEST

- Turn Engine "Off"

- Key turned to "On" position (without starting engine)

- Apply the Service Brake

- Release Parking Brake

- Then take foot OFF of the Service Brake

- TIME FOR 1 MINUTE

- Watch Air Pressure Gauge (after initial drop - pressure should not drop more than 2 PSI in one minute)

APPLIED AIR PRESSURE TEST

- Step on Service Brake and hold

- TIME FOR 1 MINUTE

- Watch Air Pressure Gauge (after initial drop - pressure should not drop more than 3 PSI in one minute)

PUMP DOWN TEST

- Pump brakes to release air pressure (do not rabbit punch or stab brakes)

- Watch air gauge (low pressure warning light and audible alarm activate between 55-65 PSI)

- Continue Pumping Brakes (spring brake "pops" out at 30-40 PSI)

BUILDING AIR PRESSURE

- Start Bus (H-i-g-h I-d-l-e)

- Watch Gauge (low pressure light and alarm go out between 55-65 PSI)

- Air Compressor "CUTS OFF" Between 120-125 PSI (Whoosh sound as governor tells the air compressor to stop pumping air.)

PARKING BRAKE CHECK

- (chocks under tires & seatbelt on)

- Apply Service Brake to Put Bus in Reverse (Open driver's window, acknowledge back-up alarm, release service brake, add throttle to 1000RPM, brake should hold.)

- Apply Service Brake to Put Bus in Drive (release service brake, add throttle to 1000RPM, park brake should hold)

HARD/SOFT BRAKE

- CHECK BEFORE LEAVING THE YARD AT 5MPH (working properly, does vehicle pull to one side or the other.)

EQUIPMENT CHECK (top to bottom, left to right)

- Insurance and registration (correct asset, not expired)

- Seatbelt (secure, pulls, latches, releases, retracts, not cut, or frayed)

- Driver's Window (opens, closes, clean not cracked or broken, inspection sticker is current)

- Camera & Hard Drive (yellow box, PMS)

- PA System (PMS, works inside & out)

- AM/FM Radio (PMS, works, interior & exterior)

- Dome Lights (operational)

- Strobe Lights (turn on, l-e-a-v-e on)

- Heated Mirrors (check when conditions allow)

- Step Heater (defrost stairs when needed)

- Sun Visor (clean & pms)

- Student Mirror #7 (clean, pms, adjusted for me)

- Fan left (pms, wires not frayed)

- Camera (secure, wires not frayed)

- Body Fluid Kit & First Aid Kit (pms, taped & dated)

- Fan right (pms wires not frayed)

- Head bumper above stairwell (pms)

MIDDLE

- Mirrors 1,2,3 (clean, not cracked or broken, adjusted to me)

- Windshield (clean, not cracked, no chips larger than a quarter, no chips/cracks in line of sight)

- Mirrors 4,5,6 (clean, not cracked or broken, adjusted to me)

BOTTOM

- Accident Packet (accident forms)

- Adjust Mirrors (adjusted to me)

- Rear Heater (2 switches to me)

- Noise Suppressor Switch (look at am/fm radio, light should go off)

- Boost Pump (aux water pump)

- Mid-Ship Heaters (2 switches, high & low)

- Drivers Heater (high & low)

- Master Switch (turn on)

- Hazard Flasher Switch (turn on, leave on, check indicator on the dash)

- Student Ambers (Turn on, leave on)

- Headlights (activate high beams - check indicator on dash, leave on)

- Windshield Wiper (spray fluid, low, high)

- Steering Wheel Play (no more than 2" of play) (turn steering wheel all the way to the left)

- Horn (check)

- Bendix (pms)

- 2-Way Radio (pms, turn on)

- Left and Right Fan (low and high)

- Floor Heater (low and high)

- Zonar (pms)

#1 WALK-AROUND

(to check hazards, student ambers, main exterior lights & reflectors)

- Wedge Brake Stick (wedge between seat & service brake)

- Check the following exterior lights for operation: (front hazzard lights, marker lights, clip clearance lights w/corresponding reflectors, student ambers, high beam, brake lights, rear hazzard lights, are working, clean, not missing or broken, operational, pms)

- Board the bus (close door, remove brake stick)

#2 WALK-AROUND

(to check left turn signal, student reds, exterior lights, reflectors, and signs, tires, and under the bus, everything else exterior)

- Deactivate Hazards

- Deactivate High Beams

- Activate Left Signal (check indicator on dash)

- Activate Reds

- Turn Steering Wheel to the Left

- Open Door (check red indicator on dash)

- Check Passenger Lights (stairwell and entry overhead, operational, pms)

FRONT OF BUS

- Radio & CB Antenna (pms)

- Student Reds (PMS, not broken, clean, operational)

- Clip Clearance Lights (PMS, not broken, clean, operational)

- School Bus Sign (clean & visible)

- Left Front Marker Light (PMS, not broken, clean, operational)

- Hand Grasp (pms)

- Passenger & Crossover Mirrors (pms, not broken, no stickers, adjusted to me)

- Windshield Wipers (PMS, proper tension, pliable, no cuts, not torn, washer hoses have no abc's, wires have not cuts, cracks, or frays, pms)

- Driver & Crossover Mirrors (pms, not broken, no stickers, adjusted to me)

- Passenger Turn Signal (PMS, not broken, operational)

- Headlights Low Beam (PMS, operational, clear, no condensation, not broken, operational)

- Drivers Turn Signal (PMS, operational, not broken, operational)

- Lower Safety (Crossing) Arm (PMS, deployed in conjunction with stop arm, proper tension, operational)

- Bumper (PMS, not damaged, foot holes clear)

- License Plate (pms, clean, visible)

- Tow Hooks, (pms)

- Air Tanks (look through the foot holes in the bumper - no audible leaks)

DRIVER'S SIDE

- Student Light (PMS, operational, clear, not broken, operational)

- Driver Window (secure, inspection sticker current)

- Electrical Box (PMS, Must have 6 spares if it is a fuse box)

- Windshield Fluid (PMS, cap secure, sufficient fluid)

- Stop Sign Arm (PMS to the bus frame, extends fully, red working lights, clean, not broken, wires connected, not bare or frayed, operational)

- Drivers Side (turn) Lights (PMS, operational, not broken)

- Auxiliary Heater (PMS, not leaking, wires connected and not bare or frayed, exhaust pipe secure)

STEERING

- Gear Box & Hoses (PMS, not leaking, no damage, not missing nuts or bolts, hoses: secure not leaking. Connected to the...)

- Pitman Arm (PMS, not missing nuts or bolts, secured with castle nut and cotter pin, not worn)

- Drag Link (PMS, not missing nuts or bolts, secured with castle nut and cotter pin, not worn.)

- Third Axle Arm (PMS, not missing nuts or bolts, secured with castle nut and cotter pin, not worn.)

- Tie Rod (PMS, not missing nuts or bolts, secured with castle nut and cotter pin, not worn.)

- U Joints: properly mounted & secured, properly greased.

SUSPENSION

- (front) Spring Hangers (PMS, secured to the frame, no WDC's, connected to...)

- Leaf Springs (PMS, secured with the (shackle & U Bolts...)

- Shackle (PMS, no missing nuts or bolts, not broken or cracked)

- U Brackets & U Bolts (PMS, no missing nuts or bolts, not cracked, or broken)

- Shock (PMS, no missing nuts or bolts, no dents, NO LEAKs)

BRAKE SYSTEM

- Brake Line/Hoses (couplings/fittings are secure, no ABC's, not cracked, worn, or frayed, no leaks)

- Brake Chamber (PMS, no dents/cracks, no leaks, no loose or missing clamps, secured with belly band clamp)

- Slack adjuster & Push Rod (PMS, no missing nuts or bolts, no more than 1" play, not bent, broken, loose, or missing parts)

- Shoes (not worn thin)

- Drums/Rotors (no cracks, dents or holes, no loose/missing bolts, no contaminants, grease, or oil, etc.)

(LEFT) FRONT TIRE ICD (Inflation, Condition, Depth)

- Air Pressure (inflation)(checked with gauge)

- Condition (condition) (tire walls free of ABC's, no detectable leaks)

- Tread (depth) (no less than 4/32nd depth, no recaps, evenly worn, not cuts, or other damage.)

- Rim (no welds, dents, cracks)

- Valve Stem (secure w/cap, opposing holes)

- Lug Nuts (tight, check with hand, not missing, no holes, no rust trail around nuts, no shiny threads indicating loose nuts)

- Axle Cover (PMS, no leakage)

- Mud Flap (PMS, not damaged)

- Frame and Crossmembers (No WDC ((welds, dents, cracks)), or holes, not bent, twisted, no loose or missing crossmembers, no missing nuts or bolts)

- Differential (no damage or leaks)

- DEF Tank (secure, fluid is more than 1/8th)

LEFT MID-SHIP EXTERIOR

- Mid-Ship Marker Light (PMS, not broken, correct color: amber)

- All Reflective Tape & Reflectors (Emergency exits, windows, door, length of bus... none broken and proper color)

- Emergency Door (opens, locks in the open position, alarm buzzes, safety strap, gasket intact & pliable)

- Frame and Crossmembers (No WDC ((welds, dents, cracks)), or holes, not bent, twisted, no loose or missing crossmembers, no missing nuts or bolts)

(LEFT) REAR TIRE ICD (Inflation, Condition, Depth)

- Air Pressure (check with gauge)

- Condition (tire walls free of ABC's, no detectable leaks)

- Tread (no less than 2/32nd depth, no recaps, evenly worn, not cuts, or other damage.)

- Rim (no welds, dents, cracks)

- Valve Stem (2 valve stems, secure w/cap)

- Lug Nuts (tight, check with hand, not missing, no holes, no rust trail around nuts, no shiny threads indicating loose nuts)

- Axle Cover (PMS, no leakage)

- Mud Flap (PMS, not damaged)

- Brake Line/Hoses (couplings/fittings are secure, no ABC's, not cracked, worn, or frayed, no leaks)

- Brake Chamber (PMS, no dents/cracks, no leaks, no loose or missing clamps, secured with belly band clamp)

- Slack Adjuster & Push Rod (PMS, no more than 1" play, not bent, broken, loose, no missing nuts or bolts)

- Shoes or Pads (not worn thin)

- Drums or Rotors (no contaminants, grease, or oil, etc.)

- BRAKE STICK BETWEEN TWO TIRES (no foreign objects between tires)

- Spring Hangers (PMS, no missing nuts or bolts, not cracked or broken)

- Leaf Springs (PMS, no missing nuts or bolts, not missing, shifted, cracked, or broken)

- U Brackets & U Bolts (PMS, no missing nuts or bolts, not cracked or broken)

- Air Spring (PMS, no ABC's, no leaks)

- Shock (PMS, not leaking)

- Frame and Crossmembers (No WDC ((welds, dents, cracks)), or holes, not bent, twisted, no loose or missing crossmembers, no missing nuts or bolts)

REAR OF BUS

- Left Rear Marker Light (PMS, not broken, correct color: red)

- Two Reflectors (clean, visible, red)

- Student Reds (PMS, operational, red, not broken)

- Student Ambers (PMS, operational, amber, not broken)

- Clip Clearance Lights (PMS, red, not broken)

- School Bus Signs (clean, visible)

- Rear Window Exit (clearly marked, outlined w/reflective tape, not cracked, or broken)

- Rear of Bus (outlined with reflective tape)

- Left Turn Signal (PMS, operational, amber, not broken)

- 4 Taillights (PMS, operational, red, not broken)

- Reverse Lights (PMS, clear, not broken)

- License Plate (PMS, clean, current, matches front)

- Bumper and Tow Hooks (PMS, not damaged)

(RIGHT) REAR TIRE ICD (Inflation, Condition, Depth)

- Air Pressure (check with gauge)

- Condition (tire walls free of ABC's, no detectable leaks)

- Tread (no less than 2/32nd depth, no recaps, evenly worn, not cuts, or other damage.)

- Rim (no welds, dents, cracks)

- Valve Stem (2 valve stems, secure w/cap)

- Lug Nuts (tight, check with hand, not missing, no holes, no rust trail around nuts, no shiney threads indicating loose nuts)

- Axle Cover (PMS, minimal to no leakage)

- Mud Flap (PMS, not damaged)

- Brake Line (PMS, no ABC's, no frays, no leaks)

- Bake Chamber (PMS, no dents, no leaks)

- Slack adjuster & Push Rod (PMS, no missing nuts or bolts, no more than 1" play, not bent, broken, loose, or missing parts)

- Shoes (not worn thin)

- Drums/Rotors (no cracks, dents or holes, no loose/missing bolts, no contaminants, grease, or oil, etc.)

- BRAKE STICK BETWEEN TWO TIRES (no foreign objects between tires)

- Frame and Crossmembers (No WDC ((welds, dents, cracks)), or holes, not bent, twisted, no loose or missing crossmembers)

- Spring Hangers (PMS, no missing nuts or bolts, not cracked or broken)

- Leaf Springs (PMS, no missing nuts or bolts, not missing, shifted, cracked, or broken)

- U Brackets & U Bolts (PMS, no missing nuts or bolts, not cracked or broken)

- Air Spring (PMS, no ABC's, no leaks)

- Shock (PMS, no missing nuts, or bolts, not leaking)

- DRIVESHAFT (not bent, twisted, cracked, U-Joints secure and free of foreign objects, properly greased.)

- SAFETY LOOP / GUARD / BRACKET (for driveshaft) (PMS, no missing nuts or bolts.)

- DIFFERENTIAL (no damage or leaks, no missing nuts or bolts)

- Oil Pan (back under left-side of mud flap, no leaks, dents)

- Transmission Fluid Pan (back under right-side of mud flap, no leaks, dents)

- Frame and Crossmembers (No WDC ((welds, dents, cracks)), or holes, not bent, twisted, no loose or missing crossmembers. No missing nuts or bolts.)

RIGHT MID-SHIP EXTERIOR

- Mid-Ship Marker Light (PMS, not broken, correct color: amber)

- All Reflective Tape & Reflectors (windows, length of bus... none broken and proper color)

(RIGHT) FRONT TIRE ICD (Inflation, Condition, Depth)

CRANK STEERING WHEEL ALL THE WAY TO THE RIGHT

- ACTIVATE (R-I-G-H-T) TURN SIGNAL

- Drivers Side (turn) Lights (PMS, operational, correct color, not broken)

- Air Pressure (check with gauge)

- Condition (tire walls free of ABC's, no detectable leaks)

- Tread (no less than 4/32nd depth, no recaps, evenly worn, not cuts, or other damage.)

- Rim (no welds, dents, cracks)

- Valve Stem (secure w/cap)

- Lug Nuts (tight, check with hand, not missing, no holes, no rust trail around nuts, no shiney threads indicating loose nuts)

- Axle Cover (PMS, minimal to no leakage)

- Mud Flap (PMS, not damaged)

- Frame and Crossmembers (No WDC ((welds, dents, cracks)), or holes, not bent, twisted, no loose or missing crossmembers)

- Close Service Door

- Deactivate Master Switch

TURN OFF BUS

- Child Check (Horn sounds three times)

- Turn Bus Back On

- Idle High

BUS INTERIOR INSPECTION

Walking to the back of the bus:

- Seat backs (not broken, PMS to floor, no vandalism)

- Check (Front) Emergency Hatch on ceiling (properly labeled, clear, opens, buzzes, latches)

- Check Emergency Door (properly labeled, clear opens, buzzes, locks)

- Check (Rear) Emergency Hatch on ceiling (properly labeled, clear, opens, buzzes, latches)

- Check Strobe Light (works, not broken)

- Check (Rear) Emergency Window (properly labeled, clear, opens, buzzes, latches)

Walking to the front of the bus:

- Check seat bottoms (not broken, cushions are securely attached to the seat frames, no vandalism)

- Check Front Emergency Windows (Properly labeled, clear, opens, buzzes, latches)

- Check Heaters (no leaks)

SCHOOL BUS INSPECTION PROGRAM

RESOURCE INFORMATION

49 CFR PARTS 570.1-570.63, Vehicle in Use Inspection Standards

49 CFR PARTS 400-599, Federal Motor Vehicle Safety Standards

49 CFR PARTS 393, 396, Federal Motor Carrier Safety Regulations

49 CFR APPENDIX G to Subchapter B, Minimum Periodic Inspection Standards

81

SCHOOL BUS RECOMMENDED OUT-OF-SERVICE CRITERIA

BODY EXTERIOR

A. Any panel, rub rail or trim that is loose, torn, dislocated or protruding from the surface of the bus, creating a hazard (393.203); or

B. Any engine, battery or other door that is not properly secured (393.203).

BODY INTERIOR

Aisle

A. Aisle does not have the required clearance (571.217); or

B. Obstructions in aisle that prevent passengers from egress to emergency exits (393.62) (393.203).

Door (Entrance)

A. The student entrance door does not open or close properly;

B. Door control handle does not lock in the closed position; or

C. Door is equipped with a padlock or similar locking device (excludes interlock systems).

Floor

Floor not maintained to prevent slipping or tripping by passenger(s).

Handrail

A. Handrail loose or missing; or

B. Handrail fails the nut/drawstring test as defined by NHTSA.

Panels

Any panel (eg., ceiling, side or wheel well) protruding, having sharp edges or not secured so is likely to cause injury.

Seat (Driver)

A. Driver seat is not securely fastened to vehicle and/or fails position; or maintain adjusted (393.93)

B. Any part of the driver's safety restraint assembly is missing, not or defective as to prevent proper securement of occupant [393.93(a)(b)] (571.209).

Seat(s) and Barrier(s)

A. Any seat or barrier that is not securely attached to the vehicle (393.91)-

B. Any seat or barrier material(s) that compromises the integrity of compartmentalization and occupant protection (571.222); or

C. Seat spacing fails to comply with 571.222.

Stepwell

A. Any part of the step well or support structure that is damaged; or

B. Any part of the step well tread that is loose, torn or damaged that would present a

tripping hazard.

BRAKE SYSTEM(S)

Adjustment

Any one brake beyond the adjustment limit (See Table 1: Brake Adjustment Specifications.)

Air System

A. Absence of effective braking action upon application of service brakes [393.48 (a)];

B. Audible air leak at chamber (e.g., ruptured diaphragm, loose chamber clamp, etc.) [386.3(a)(1));

C. If an air leak is discovered and either the primary or secondary reservoir pressure is not maintained when these conditions exist [396.3(a)(1)):

1. Governor is cut-in;

2. Reservoir pressure is between 80-90 psi;

3. Engine is at idle; and

4. Service brakes are either fully applied or released; or

D. ABS malfunction indicator light not functioning as designed or illuminated on all ABS required vehicles.

Axle Brakes, General

A. Chamber size mismatched on axle [393.47(b)];

B. Mismatched brake chamber long stroke verses regular stroke [393.47(b)]; or

C. Mismatched slack adjuster length [393.47(c)].

Brake Shoe/Pad/Lining

A. Any lining thickness less than allowed by 393.47;

B. Lining pad is cracked, broken, not firmly attached or missing (393.47) (surface or heat cracks in the lining should not be considered out of service);

C Ute friction surface of drum, rotor or friction material are contaminated by oil, grease or brake fluid (393.47); 0. Loose or missing component (e.g., chambers, spiders, support brackets) (393.47);

E. Fails to make contact with drum/rotor (eg., frozen, binding, uneven) [393.48(a)];

F. Absence of braking action on any axle (e.g., failing to move upon application of a wedge, S-cam, cam or disc brake);

G. Rotor or drum has evidence of metal to metal contact on the friction surface [393.47(d)(1)]; or

H. Brake pad, lining or shoe missing [393.47(a)],

Drums/Rotors

A. External crack(s) that open upon application [393.47(a)]; or

B. Any portion of the drum or rotor (discs) missing, broken, misplaced or cracked through rotor to center vent [393.47(a)],

Hoses and Tubing

A. Brake hose with any damage extending through [393.45(a)]; the outer reinforcement ply

B. Audible leak at other than a proper fitting or connection [393.45(a)];

C. Any bulge or swelling when brake are applied (393.45(a)];

D. Any restriction due to cracked, broken or crimped line/hose [393.45(a)]- or

E. Any line, tubing, hose or connection that is not constructed to meet standa (571.106). 30 3rd

Hydraulic Brake System

A. System brake failure light or low fluid light on or inoperative (393.51)-

B. Reservoir is below minimum level [393.45(a)] (571.106);

C. Any seeping, leaking or swelling of hose(s) under pressure [393.45(a)]-

D. Any leak in master cylinder unit [393.45(a)] (571.106).

E. Any observable fluid leak in the brake system;

F. Brake failure warning system is missing, inoperative, disconnected, defective, or activated while the engine is running with or without brake application [393.51(b)];

G. ABS malfunction indicator light not functioning as designed or illuminated on all ABS required vehicles.

Parking Brake

A Fails to hold vehicle in stationary position on normal roadway conditions (absence of ice or snow) in forward or reverse (393.41) [571.105 S5.2.1 and S5.2.3(b)].

B. Parking brake warning lamp fails to function as designed.

Pedal Reserve

No pedal reserve with engine running [393.40(b)].

Power Assist Unit

Fails to operate [396.3(a)(1)].

DIFFERENTIAL

Cracked or leaking housing [393.207(a)].

DRIVESHAFT

A. Driveshaft guard loose, missing, improper placement or bent (393.89); or

B. Universal Joint(s) worn or faulty, or obvious welded repair [393.209(2)(d)].

ELECTRICAL/BATTERY

Battery

A. Battery not secured (393.30);

B. Signs of leaking or excessive corrosion; or

C. Battery lacks cranking capacity to start engine.

Cables

A. Electrical cabe insulation chafed, frayed, damaged or compromised insulation burn, causing bare cable to be exposed (393.28, 396.3(a)(1)];

B. Loose or corroded connections at battery posts or compromised insulation protection to electrical components (393.28, 393.77(b), 396.3(a)(1)]; or

C. Missing or damaged protective grommets insulating main electrical cabels through metal compartment panes (393.30).

Components

A. Broken or unsecured mounting of electrical components [396.3(a)(1)]; or

B. Electrical cable unsupported, hanging or missing clamps that may cause chafing or frayed conditions [393.28, 396.3(a)(1)].

Windshield Wipers

A. Inoperative, missing or damaged wiper (393.78); or

B. Wiper does not clean sweep area of driver's windshield (393.78).

EMERGENCY EQUIPMENT

A. Fire extinguisher missing, not of proper type or size, not fully charged, has no pressure gauge, is not secured or is not readily accessibe to the driver or passengers (393.78); or

B. Any additional state-specific equipment (e.g., first aid kit, body fluid kit, webbing cutter and emergency reflectors) that fails to meet state specification and places the vehicle out of service; or

C. Missing emergency traingles (571.125).

EMERGENCY EXITS

A. Any emergency door, window or roof hatch that fail to open freely or completely as defined in 571.217;

B. Door prop-rod device is missing or inoperative (571.217);

C. Any emergency exit equipped with a padlock or similar locking device (excludes interlock systems);

D. Any vehicle that lacks the required number of emergency exits (571.217);

E. Any emergency exit not properly labeled and marked both inside and outside the vehicle as specified by 571.217;

F. Any item or modification that reduces the size of the opening and limits egress to the emergency exit by all passengers; or

G. Emergency exit warning device is not audible in the driver seating position and/or the vicinity of the emergency door or window (571.217).

ENGINE

A. Any critical component that fails to function as designed (396.3); or

B. Any fluid leak that would affect the safe operation of the vehicle (396.3).

EXHAUST SYSTEM

A. The exhaust system is leaking or discharging directly below or at a point forward of the driver or passenger compartment [393.83(g)]; or

Note: Does not apply to proper venting for emission systems.

B. No part of the exhaust system shall be located and likely to result burning, charring or damaging the electrical wiring, the fuel supply or any combustible part of the vehicle [393.83(a)],

FUEL SYSTEM

CNG or LPG Fuels

A. Any fuel leakage from the CNG Or LPG system detected audibly or by smell and verified by either a bubble test using non-ammonia, non-corrosive soap solution, or a flammable gas detection meter [396.3(a)(1)!.

Note: Verification is needed to ensure that the sound is not either internal to the fuel system (such as gas flowing in a pressure regulator, or pressure equalizing between manifold tanks) or a leak in the air brake system.

B. Any fuel leakage from the CNG or LPG system detected visibly (evidence such as ice buildup at fuel system connections and fittings) and verified by either a bubble test using non-ammonia, non-corrosive soap solution, or a flammable gas detection meter [396.3(a)(1)].

Note: Some brief fuel leakage or decompression may occur during refueling, causing temporary frosting of CNG or LPG fuel system parts. If the vehide has been refueled shortly before inspection, care must be taken to distinguish these temporary frosting occurrences from actual leaks.

Liquid Fuels

A. Any part of the fuel tank or fuel system not securely attached to the vehicle (393.65);

B. A fuel system with a dripping leak at any point (393.67 Tank); or

C Dripping leak (396.3(a)(1) leak other than tank); or

D. Missing fuel cap or system does not seal as designed.

LAMPS/SIGNALS

A. Any one of the following lamps not working: brake, turn signal, tail, head (low beam), school bus overhead warning light (amber or red), hazard warning or stop arm lamp (571.108, 571.131);

Note: vehicle LED lamps must have considered not working more than 25% of the diodes unlit to be

B. Horn fails to function as designed (393.81);

C. Any critical brake, telltale lamp, buzzer or gauge that fails to to function as designed;

D. Required stop arm(s) fail to operate with overhead red lights as mandated (571.131); or

E. If equipped, a crossing control device fails to extend and retract as designed.

MIRRORS (571.111)

A. Any mirror required to provide the driver with the entire field of view, missing, damaged, clouded or otherwise obscured so as to place children in a hazardous position;

B. Any crossover mirror system or portion thereof that fails to hold a set adjustment;

C. Any crossover mirrors directed to view any area other than for which they were intended; or

D. Any part of the required field of vision obscured or not visible from the driver seated position.

STEERING SYSTEM

Ball/Socket Joints

A. Any movement under steering load of a nut stud [396.3(a)(1)];

B. Any motion, other than rotational, between any linkage member and it attachment point of more than % inch measured with hand pressure only [393.209(d)]; or

C. Any obvious welded repair [393.209)(d)].

Front Axle Beam

Any crack(s) or obvious welded repair [396.3(a)(1)],

Nuts

Loose or missing fasteners on tie rod, pitman arm, drag link, steering arm or tie rod arm [396.3(a)(1)],

Pitman Arm

A. Looseness of the pitman arm on the steering gear output shaft [393.209(d)]; or

B. Any obvious welded repair [396.3(a)(1)] [393.209(d)],

Power Steering

A. Auxiliary power assist cylinder loose [393.209(e)),

B. Power steering system belts frayed, cracked or slipping [393.209(2)(e)J, or

C. Power steering system leaking or insufficient fluid in reservoir [393.209(2)(e)]

Steering

A. Any modification or condition that interferes with free movement of any steering component [393.209(d)]; or

B. Steering travel restricted through the limit of travel in both directions [570.60(c)].

Steering Column/Wheel

A. Absence or looseness of U-bolts or other positioning part(s) [393.209(c)];

B. Welded or repaired universal jointfs) [393.209(d)];

C. Steering wheel not properly secured [393.209(a)]; or

D. Steering wheel lash/free play exceeds performance test (see Table #2) [393.209(b)].

Steering Gear Box

A. Mounting bolt(s) loose or missing [393.209(d)];

B. Crack(s) in gearbox or mounting brackets (393.209(d)) [396.3(a)(1)];

C. Any obvious welded repair(s) [396.3(a)(1)] [393.209(d)]; or

D. Looseness of yoke-coupling to the steering gear input shaft [393.209(d)].

Tie Rods/Drag Links

A. Loose clamp(s) or damp bolt(s) on tie rod or drag link(s) [396.3(a)(1)]; or

B. Any looseness in any threaded joint [396.3(a)(1)],

SUSPENSION COMPONENTS

Air Suspension

A. Deflated air suspension (one or more deflated air spring/bag) (393.207(f)]; or

B. Air spring/bag is missing, broken, or detached at either the top or bottom (393.207(f)].

Axle Parts/Members

A. Any U-bolt or other spring to axle clamp bolt(s) which are cracked, broken, loose or missing [393.207(a)];

B Any axle, axle housing, spring hanger(s), or other axle positioning parts which are cracked, broken, loose or missing that results in shifting of an axle from its normal position (393.207(a)];

C. Any worn (beyond manufacturer specifications) or improperly assembled U-bolt, shock, kingpin, ball joint, strut, air bag or positioning component [570.61 (a)];

D. Any spring hanger, assembly part or portion of leaf which is broken, separated or missing [393.207(c)]; or

E. Any broken coil spring (393.207(d)).

Bumpers

A. Front bumper is missing or not properly secured [393.203(e)]; or

B. Rear bumper is missing or not secured (393.86).

Chassis/Frame/Unibody

A. Any cracked, loose, sagging or broken, frame side rail. [393.201(a)];

B. Any damage permitting the shifting of the body or imminent collapse of frame [393.201(a)];

C. Any cracked, loose, broken frame member affecting support of functional components (e g., steering gear, engine, transmission, body part or suspension) (393.201(a));

D. Any crack 1 1/2 inch or longer in the frame side rail web which is directed toward bottom flange [393.201(a)]; or

E. Any crack extending from the frame side rail web around the radius and into the bottom flange (393.201(a)).

Crossmembers

A. Any cross member, outrigger, or other structural support which is cracked, missing or deformed that affects the structural integrity of the vehicle (393.201);

B. Three or more adjacent crossmembers broken or detached (393.201); or

C. Any area of the floor that is sagging or soft due to broken crossmembers (393.201).

Outriggers/Body Supports

Any cross member, outrigger or other structural support which is cracked, missing, deformed

or has rust holes where damage affects the safe operation of the vehicle.

TIRES/WHEELS/HUBS

Hub

A. Excessive wheel bearing or kingpin play that exceeds 1/4 inch (393.70) (570.61).

B. Any bearing (hub) cap, plug, or filler plug that is missing or broken, allowing an open view into hub assembly [396.3(a)(1)];

C. Smoking from wheel hub assembly due to bearing failure [396.3(a)(1)];

D. When any wheel seal is leaking. This must include evidence of contamination of the brake friction material [396.5(b)];

Note: Grease/oil on the brake lining edge, back of shoe, or drum edge and oil stain with no evidence of fresh oil leakage are not conditions for an out-of-service violation.

E. Lubricant is leaking from the bearing hub and is accompanied by evidence that further leakage will occur [396.5(b)]; or

F. No visible or measurable of lubricant showing in bearing hub [396.5(a)).

Tire Inflation

Tire is flat or has noticeable leak [393.75(a)(3)],

Tire Sidewall

A. Any sidewall cut, worn or damaged to the extent that the steel or fabric cord is exposed (393.75(a)]; or

B. Any observable bump, bulge or know related to sidewall or tread separation [393.75(a)].

Tire Tread Depth

A. Any front tire worn to less than 4/32 inch [393.75(b)]; or

B. Any rear tire worn to less than 2/32 inch [393.75(c)].

Tire Type

A. Any school bus operated with regrooved, recapped or retreaded tires on the front axle [393.75(d)); or

B. Any tire not of proper type (e.g., load range, size, mismatched on axle).

Wheels/Rims/Spiders

A. Any nuts, bolts, studs, lugs or holes that are elongated, broken, missing, damaged or loose [393.205(b)];

B. Any cracked or broken wheel or rim [393.205(a)]; or

C. Any lock or slide ring broken, cracked, improperly seated, sprung or has mismatched rings [393.205(a)],

WHEELCHAIR LIFT-EQUIPPED VEHICLES

A. Wheelchair lift does not function as designed or is inoperable;

B. Platform lift manufactured after April 1, 2005 must meet all the following criteria, (as referenced in FMVSS 403 and 404):

1. Jacking prevention;

2. Manual backup operating mode;

3. Interlocks to prevent forward or rearward mobility of the vehicle unless lift stowed and lift doors are closed;

4. Wheelchair retention device; and

5. Platform outer barrier, inner roll stop and threshold warning device.

C. Any hydraulic line leaking during lift operation;

D. Wheelchair restraint system is missing, incomplete or improperly installed loose damaged or does not adhere to the securement manufacturer's recommendations" or

E. Any required wheelchair occupant restraint system not in compliance (571.222)

WINDOWS

A. Any glass or glazing that is broken through or missing (393.60),

B. Any glass not of approved type (393.60(a));

C. Windshield has discoloration or other damage in that portion extending upward from the height of the topmost portion of the steering wheel, but not including a two-inch border at the top and a one-inch border at each side of the windshield or each panel thereof, except as follows:

1. Color or tint applied by the manufacturer for the reduction of glare;

2. Any crack not over 1/4 inch long, if not intersected by any other crack;

3. Any damaged area, that can be covered by a disc 3/4 inch in diameter, if not closer than three inches to any other such damaged area; or

4. Driver's side area window(s) have chips, clouding, or cracks that obscure the driver's vision [393.60(c)]; or

D. No operable defrosting and defogging system to clear the driver's windshield (571.103).